You can use a Threadlocker for components’ nuts, bolts, screws, and other threaded fasteners to safely secure them in place. A threadlocker protects against shock, vibration, temperature, and other external factors loosening your threaded connections.

On the other hand, you may also require a thread sealant to fill gaps or space between threaded fasteners in many situations.

So, in the debate of Thread Sealant vs. Threadlocker, which one should you side with? I’ll review the features, ideal uses, and differences between Threadlocker and Thread Sealant in this article.

Read More: Leak Lock Vs. Loctite

Thread Sealant vs. Threadlocker

Overview of Thread Sealant

You can use a Thread Sealant to secure threaded fasteners in various equipment into an airtight and watertight seal. Sometimes some Thread Sealants are also known as Pipe Sealants since they have various uses for plumbing.

Since Thread Sealants have widespread usage, they are available in multiple forms to best suit your specific needs. Some of the available forms of thread sealants are – liquid sealants, tape sealants, and paste sealants.

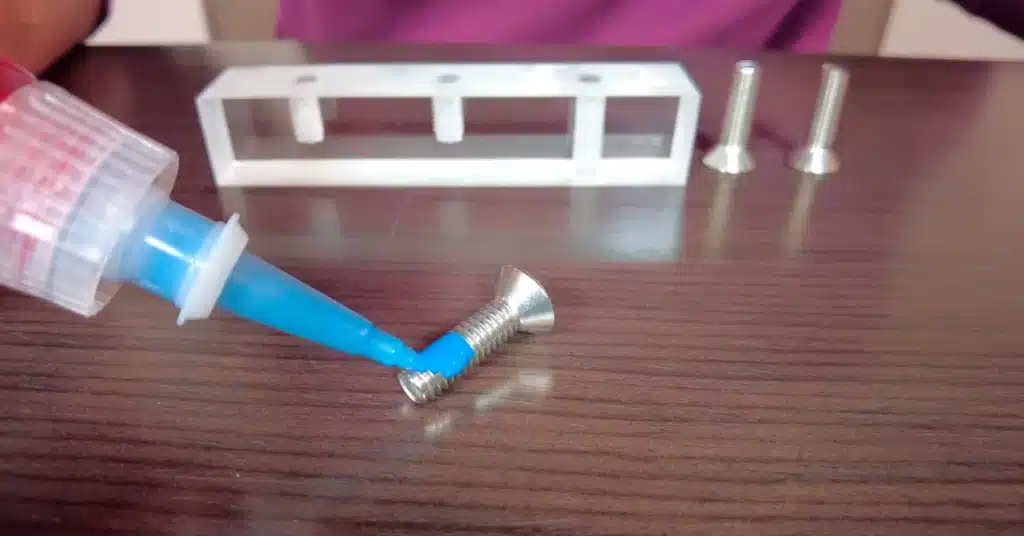

If you’re using liquid or paste sealants, you can apply thread sealants directly on the threaded fasteners using a brush or applicator provided by the manufacturer. On the other hand, if you go for tape sealants, you wrap them around the thread to seal them.

Whichever thread sealant you get, apply it to threads of pipes, fittings, or your components before you screw them together. Once you apply thread sealant, your components are safe from leakage due to thread sealant filling gaps and space between the threads.

Depending on the manufacturer and the thread sealant you pick, it can withstand various temperatures, pressure, and other environmental hazards. Furthermore, you can purchase thread sealants suitable with various materials like metal, plastic, rubber, and more.

It is important to pick the right thread sealant that suits your purpose and to ensure it can withstand temperature, pressure, or other environmental or chemical hazards your components face.

Read More: Loctite 242 vs. 243

Overview of Threadlocker

Threadlockers are adhesive, and you can use them for nuts, bolts, and other threaded fasteners to safely secure them in place. You can use threadlockers for components that risk exposure to high amounts of shock, vibration, or other environmental factors.

Many mechanical, automotive, construction, industrial, home, and other components risk their threaded fasteners loosening over time or leakage, and using a threadlocker prevents equipment failure, damage, and other hazards.

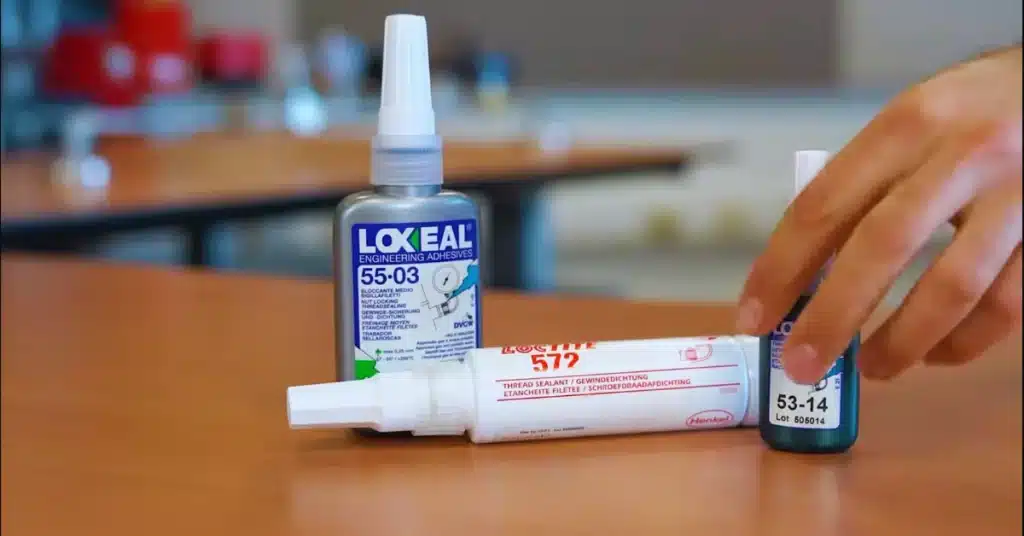

When you apply a threadlocker, it creates a strong bond between threaded fasteners. Loctite has a wide range of threadlockers available, and they work well with all metals and standard substrates like – brass, stainless steel, steel, and more.

Threadlockers are typically available in liquid form and have various viscosity options suitable to your specific needs. Threadlockers are also available in various strengths since they have various applications requiring varied strengths.

For example, Loctite offers threadlockers in various colors, indicating their strength and intended purposes. Loctite threadlockers are available in 4 colors – Red, Blue, Purple, and Green.

Read More: Loctite Vs. Permatex Threadlocker

Red Loctite is the strongest and can be used for high-strength or industrial-grade applications. Blue Loctite and Purple Loctite have medium and low strength, respectively. And lastly, Green Loctite are wicking-grade threadlocker.

It is important to pick the right strength of the threadlocker depending on your specific purposes. Threadlockers can withstand very low and extremely high temperatures, environmental hazards, and more. Furthermore, they are also tolerant to various contaminants, cutting fluids, anti-corrosion fluids, and more.

Read More: Retaining Compound vs. Threadlocker

Differences Between Thread Sealant And Threadlocker

Now let’s examine how Thread Sealants and Threadlockers differ.

Ideal Uses

You can use Thread Sealants to fill gaps between your threaded fasteners to an airtight and watertight seal. Once you apply, thread sealant fills gaps and spaces between your threaded fasteners, preventing leaks of fluids, gas, or other substances.

On the other hand, you can use Threadlocker to secure bolts, nuts, screws, and other threaded fasteners in place for components with a risk of exposure to high pressure, temperature, vibration, shock, and other factors. Once a threadlocker fully cures, it creates a strong bond and ensures threaded fasteners remain in place.

Some threadlockers can also simultaneously function as thread sealants.

Available Physical Form

Thread Sealants are available in various forms like paste, liquid, or tape.

On the other hand, Threadlockers are typically available in liquid form. Threadlockers are also available in various strengths and viscosities.

Industries and Typical Uses

Thread Sealants are widely used for various plumbing and piping systems. You can also use thread sealants for various components with threaded fasteners that require a leak-free connection.

On the other hand, threadlockers are typically used to safely secure your threaded fasteners in place for various heavy-duty, industrial, and other situations.

Can threadlocker be used as a sealant?

Does LOCTITE work as thread sealant?

Is thread sealant permanent

Last Opinion

So, what should you pick in the battle between thread sealant vs. threadlocker? It depends on you and your specific needs since the practical applications for these products are widely different.