Among marine-grade sealants, Sikaflex 291 and 3M 4200 are popular options. Both sealants are designed for use in the marine industry and have similar waterproofing properties, but there are some important differences between them.

Here, I will compare Sikaflex 291 vs. 3M 4200 to help you choose the best for your project.

Read More: Vulkem 45 SSL Vs. Sikaflex

Sikaflex 291 Vs. 3M 4200

Overview of Sikaflex 291

Sikaflex 291 is a one-part marine adhesive and sealant formulated for bonding and sealing in marine environments. It is a high-strength, moisture-curable polyurethane commonly used in the marine industry for applications such as hull-to-deck joints, through-hull fittings, portholes and hatches.

A key benefit of Sikaflex 291 is its excellent adhesion to a wide variety of substrates, including wood, fiberglass, metals, and most plastics. Additionally, it is resistant to seawater, freshwater, and weathering, making it an ideal choice for marine applications. Moreover, Sikaflex 291 is a flexible sealant that can accommodate movement and vibration, thereby reducing the risk of cracking or separation.

The application of Sikaflex 291 is quick and easy, and it can be done using a variety of tools, including spatulas and caulking guns. In most cases, it fully cures within 1-4 days. Once fully cured, it can be sanded or painted over. Sikaflex 291 is available in a variety of colors, including white, black, gray, and beige, to match the color of the substrate to which it is applied.

Read More: Best Adhesive For Foam Board To Metal

Overview of 3m 4200

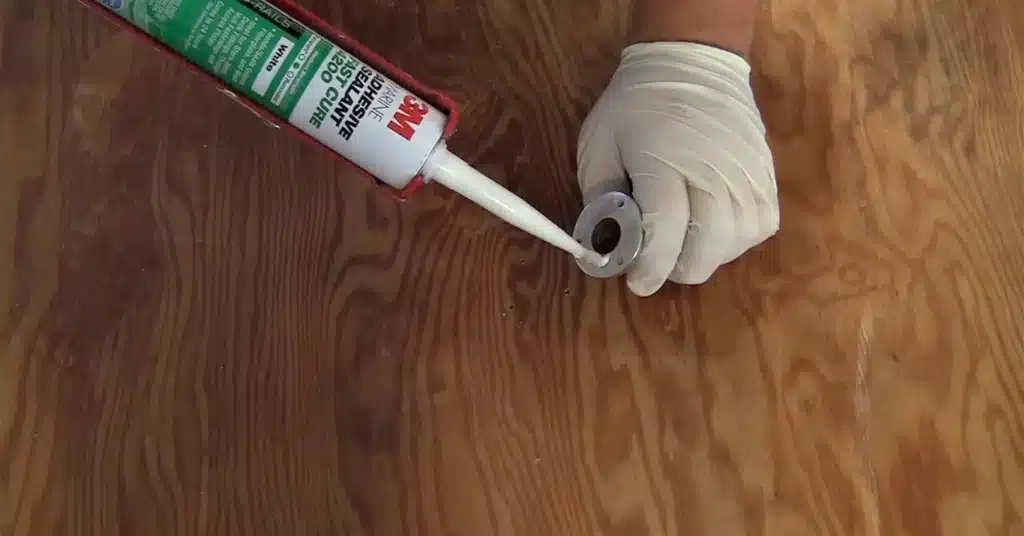

3M 4200 is a one-part adhesive sealant that is specifically designed for marine environments. It is a polyurethane-based sealant that offers excellent adhesion and flexibility, making it ideal for bonding and sealing applications on boats and other watercraft. In the marine industry, 3M 4200 is widely used to seal deck hardware, through-hull fittings, and portholes.

A flexible sealant such as 3M 4200 reduces the risk of cracking or separation by accommodating movement and vibration. It is a key advantage of 3M 4200 that it adheres well to a variety of substrates, including wood, fiberglass, metals, and plastics. In addition, it is resistant to weathering, saltwater, and freshwater, making it an ideal material for use in harsh marine environments.

3M 4200 cures moderately and can be tooled with a variety of tools, such as spatulas and caulking guns. The product can be sanded or painted over once it has fully cured, making it a versatile choice for marine applications.

Read More: 3m 5200 Vs. Sikaflex 292i

Comparison Between Sikaflex 291 and 3M 4200

Cure Time

Cure time is a major difference between Sikaflex 291 and 3M 4200. 3M 4200 takes 24 hours to fully cure, whereas Sikaflex 291 takes 1-4 days, depending on temperature and humidity. 3M 4200 may be the better choice if you need a quick cure time.

UV Resistance

Sikaflex 291 is also more UV resistant than 3M 4200. The UV resistance of sealants is important in marine applications because prolonged exposure to sunlight can cause them to break down or degrade. Sikaflex 291 is the best choice for applications exposed to sunlight.

Chemical Resistance

If your application is in contact with chemicals, 3M 4200 may be a better choice. Compared to Sikaflex 291, 3M 4200 has better chemical resistance, making it more suitable for applications involving chemicals.

Flexibility

Flexibility is another important consideration. The flexibility of Sikaflex 291 makes it a better choice for applications where there is movement or vibration. It is better to use Sikaflex 291 if you need a sealant that can withstand movement.

Availability and Cost

There is a wide range of Sikaflex 291 and 3M 4200 available, and their prices are in similar range, so availability and cost may not be a big deciding factor in the decision. But generally, 3M 4200 cost a bit more than Sikaflex 291.

How Strong Is Sikaflex 291?

How Do I Remove 3M 4200 Adhesive?

Last Opinion

It depends on your application and requirements whether Sikaflex 291 or 3M 4200 is right for you. You should consider Sikaflex 291 if your application will be exposed to sunlight and you need high flexibility. You should choose 3M 4200 if you need a sealant with a quick cure time and chemical resistance.

You can’t go wrong with either sealant, as they are both waterproof and suitable for marine applications. You should consider these factors when buying marine-grade sealants. Here, I compare Sikaflex 291 vs. 3M 4200 so that you can benefit from the long-term protection provided by these high-quality sealants.