Permatex cold weld is two-part, general purpose epoxy that eliminates the need for welding or brazing. On the other hand, JB weld is two-part epoxy that creates a strong and long-lasting bond. In this article, I will try to compare permatex cold weld vs. jb weld.

Read More: JB Weld Vs. Epoxy

Permatex Cold Weld vs. JB Weld

Overview of Permatex Cold Weld

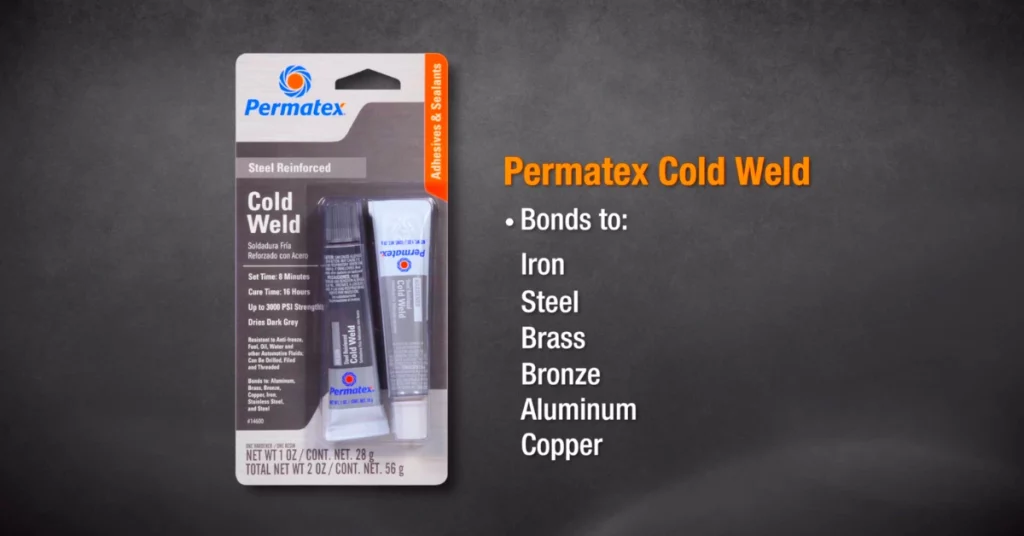

Permatex cold weld is a two-part, fast curing, high strength epoxy. It can be drilled, tapped, threaded, filed, sanded and painted once fully cured. It is resistant to most shop fluids including fuel, oil, water, and solvents and it repairs, fills and bonds iron, steel, brass, bronze, aluminum, and copper.

Its bonding compound is a 15 minute, two part adhesive. It has a filler mechanism that eliminates the need for welding or brazing. To iron, steel, brass, bronze, aluminum, and copper, it fills, fixes, and bonds.

Advantages of Permatex Cold Weld

- Within 30 minutes, you can use it.

- It is non-flammable.

- Moisture resistance is good.

- Extreme temperature resistance.

- It does not require heating.

Read More: Marine Tex Vs. JB Weld

Overview of JB Weld

The authentic cold weld two-part epoxy method, JB weld offers durable repairs to metal and other surfaces. It comes in two parts- resin and hardener. You need to mix these two parts to use them.

If you mix these two parts in an appropriate ratio of 1:1, then it will form a strong permanent bond of tensile strength of 5020 PSI after curing. It takes around 4 to 6 hours at room temperature to set to a dark gray color, and it takes 15 to 24 hours to fully cure.

Advantages of JB Weld

- Strong and long-lasting.

- Ideal for repairing metal surfaces.

- Numerous uses.

- Simple to use.

Read More: JB Weld Vs. Gorilla Glue

Which One Is The Best? Permatex Cold Weld or JB Weld?

Permatex Cold Weld is able to work well at a temperature of 150°C/300°F. On the other hand, JB Weld can withstand temperatures up to 287°C/550°F. So, if you need the bond to stay strong at extreme temperatures, then you should use JB Weld.

Permatex Cold Weld can create a strong bond with a shear strength of 3000 PSI on steel. On the other hand, JB Weld can hold a bond with a tensile strength of PSI 5020 on most materials. So, if you want your bond to hold so many weights and stay strong always, then JB Weld is the best epoxy option for you.

In terms of curing time, Permatex Cold Weld is the clear winner because it takes up to 16 hours maximum to fully cure. But on the other hand, JB Weld takes 15 to 24 hours to fully cure.

JB Weld sets to dark grey once it starts to cure. But Permatex Cold Weld can be painted once it is cured. So, if you don’t want to hamper your material’s aesthetics, then Permatex Cold Weld is the best option because you can paint it once it is fully cured.

Read More: JB Weld Marine vs. Original

How Strong Is Permatex Cold Weld?

How Long Does It Take Permatex Cold Weld to Dry?

What Will JB Weld Not Stick To?

Last Opinion

For fast curing time and paint options, you may want to use Permatex Cold Weld. But JB Weld is the sure-shot winner for an extremely strong bond and extreme temperature resistance.

Hopefully, you like this article about permatex cold weld vs. jb weld. Leave a comment below if you have any questions.