Loctite is one of the most popular adhesive manufacturers, and you’ll find a Loctite product no matter which type of glue you’re looking for. Loctite makes various kinds of adhesives like – threadlockers, sealants, instant adhesives, retaining compounds, etc., and has multiple options available for each category.

Loctite 565 and 567 are thread sealants manufactured by Loctite-Henkel and have many similarities and differences. So, in the battle between Loctite 565 vs. 567, which one should you side with and why? Please keep reading to make an informed decision, as I’ll cover what these glues offer and how they differ in this article.

Read More: Loctite 609 vs. 680

Read More: Loctite 242 vs. 243

Loctite 565 vs. 567

Overview of Loctite 565

Loctite 565 is an acrylic thread sealant manufactured by Loctite-Henkel that comes in white to off-white colors. The 565 is a high-performance thread sealant, and you can use it to seal metal pipes or fittings.

Loctite 565 is versatile when it comes to materials it suits well with, as it works well with all metals, and you can use it with – aluminum, brass, copper, stainless steel, steel, etc. Furthermore, you can also use the 565 with tapered and straight-threaded pipes or fittings.

You can use the 565 for high-performance applications since it is resistant to vibration once wholly cured. Once the 565 is fully cured, it is resistant to leakage or your components loosening due to shock or vibration. Loctite 565 can be used for household and outdoor uses, and you can use it for hydraulic systems, refrigeration, or compressor systems.

Loctite 565 is chemically based on Methacrylate Ester and has high viscosity. Even though the 565 has a high viscosity, it is thixotropic, so there is less risk of the uncured adhesive running over the surface.

Loctite 565 takes up to 24 hours for a complete cure, and the cure time depends on temperature, humidity, and which materials you use it on. You can speed up the cure time using activators.

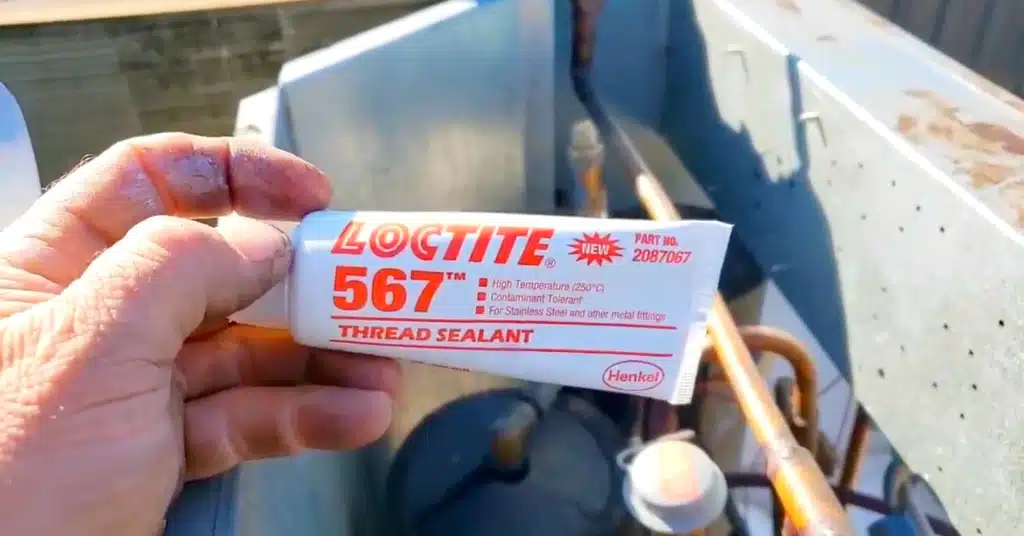

Overview of Loctite 567

Loctite 567 is a high-performance, low-strength thread sealant manufactured by Loctite-Henkel that comes off-white. Since the 567 is a low-strength sealant, you can disassemble your components easily using household tools like a wrench in the future.

Loctite 567 is a versatile adhesive that bonds well with all metals and passive substrates. Loctite 567 works well with metals like – Aluminum, Steel, Galvanized Steel, Stainless Steel, Brass, and Copper, among others. Furthermore, Loctite 567 works well with both coarse and tapered thread types.

Loctite 567 can be used in industrial settings since it can withstand high temperatures and pressure. You can use Loctite 567 for components that can be exposed to temperatures up to 204°C of temperature or pressure up to 10,000 psi.

Loctite 567 is a high-viscosity thread sealant and is thixotropic, reducing the risk of uncured adhesive running over the surface. Since the 567 can withstand extreme temperatures and pressure, you can use it for sealing leaks in steam or gas lines.

Loctite 567 uses acrylic technology to cure, and the curing process begins when the adhesive is confined in the vacuum between close-fitting metal components. Furthermore, Loctite 567 is also tolerant to contamination from various industrial oils like – cutting, lubrication, or anti-corrosion fluids.

Read More: Loctite Blue vs. Red

Differences Between Loctite 565 And 567

Now let’s examine how Loctite 565 and 567 differ.

Viscosity

Loctite 565 and 567 are both high-viscosity adhesives and are thixotropic.

Loctite 565 has a viscosity rating of 175000.0 – 525000.0 mPa·s (cP).

On the other hand, Loctite 567 has a viscosity rating of 540000.0 mPa·s.

Ideal Thread Sizes

You can use Loctite 565 for threads up to 2” in size. Loctite 565 is compatible with – 3/8 NPT, 3/8 x 24, and M10 nuts and bolts.

On the other hand, you can use the 567 for threads up to 3” in size. Loctite 567 is compatible with – 3/8 NPT, 3/8 x 24, M10, and M16 nuts and bolts.

Ideal Uses

You can use Loctite 565 for household and outdoor citations like – hydraulic systems, refrigeration, or compressor systems.

On the other hand, you can use the 567 for various heavy-duty industrial uses where your components are exposed to high temperatures and pressure, like steam or gas lines.

Last Opinion

So, which one should you side with in the battle between Loctite 565 vs. 567? It depends on your specific need for the application of the thread sealant. If you plan to work with systems that do not withstand high pressure or temperature, you can go with the 565.

If your components have the risk of being exposed to high temperature or high pressure, you can go for the 567 since it can withstand up to 204°C of temperature or pressure up to 10,000 psi.