Can you tell how sticky an adhesive is just by touching it? How sticky does something have to be to adhere paper to paper? Can you measure how much force it takes to pull two objects apart once they’re stuck?

If so, you’re well on your way to measuring stickiness! In this post, I’ll my our favorite tips and tricks for the different ways we measure the stickiness of adhesives.

I’ll also help you decide which method will work best in your situation and give examples of each technique used in industrial applications.

Read More: How to Make Adhesive Sticky Again?

Exploring the Science of Adhesion

Before we dive into the methods of measuring adhesive stickiness, let’s take a moment to understand the science of adhesion.

Adhesion is the bond formed when two different materials come in contact with each other. It’s not just a property of the adhesive itself, but also a result of the interaction between the adhesive and the materials being stuck together.

When an adhesive comes into contact with a surface, molecules from the adhesive interact with the molecules of the surface.

The resulting bond can be physical or chemical in nature. The strength of this bond determines the stickiness or tackiness of the adhesive. The stickier the adhesive, the stronger the bond.

How to Measure the Stickiness of Adhesive?

To effectively measure a substance’s stickiness or adhesive properties, you can utilize various standardized techniques. The most commonly used are the Peel, Shear, and Tack Tests.

Each test measures different aspects of an adhesive’s performance, providing a complete understanding of its overall stickiness.

Peel Test

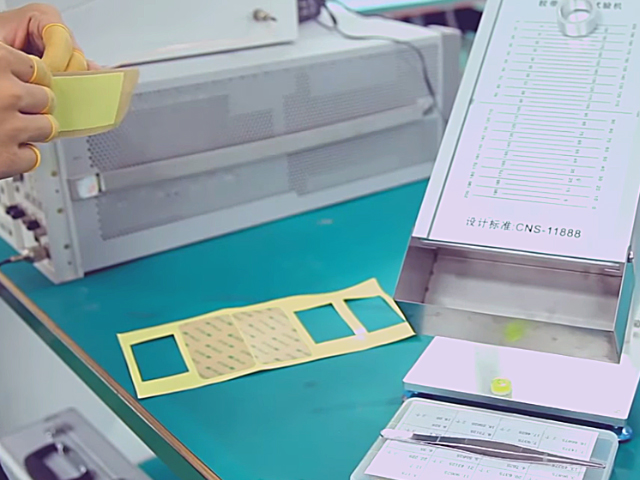

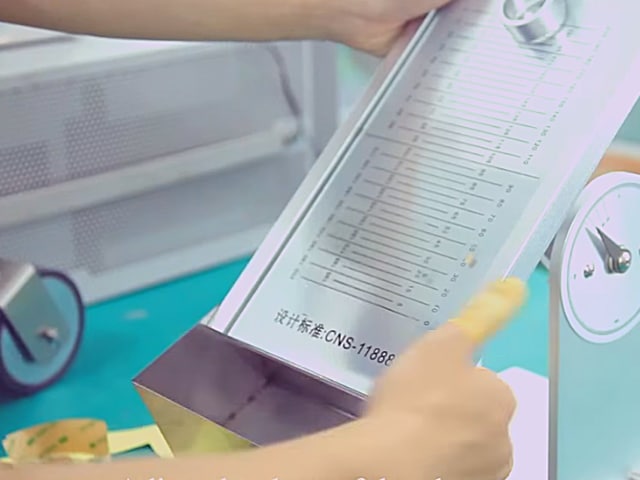

The Peel Test is one of the most widely used methods in adhesive testing. This test measures the force required to peel an adhesive tape from a standard surface at a predetermined angle and speed.

In the test, a strip of tape is adhered to a smooth surface, such as stainless steel. A machine then peels the tape off the surface at a specified angle—commonly 90 or 180 degrees—and at a constant speed.

The machine measures the force needed to peel the tape away, then calculates the adhesive’s peel adhesion.

Peel adhesion represents the adhesive’s bond strength. The higher the force needed to peel off the tape, the stronger the bond and, thus, the stickier the adhesive.

Shear Test

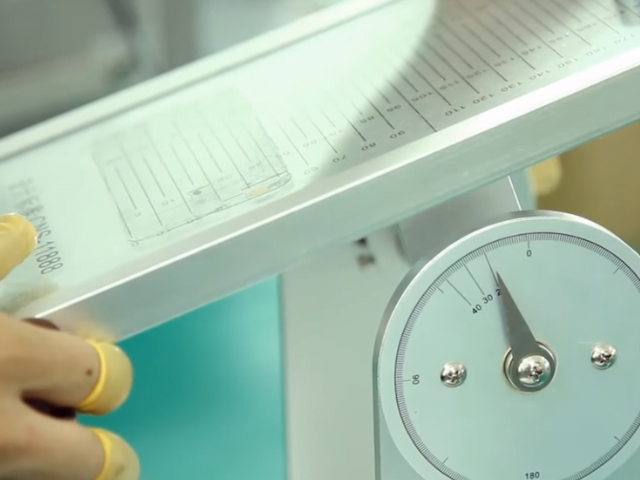

The Shear Test provides another perspective on an adhesive’s performance. This test measures the time it takes for a specified weight to cause a standard adhesive tape to slide off a standard surface, which indicates the adhesive’s resistance to shearing forces.

In the test, an adhesive tape is stuck onto a surface vertically. A specified weight is then hung from the bottom end of the tape, applying a constant force that tries to shear the tape off the surface.

The time it takes for the weight to cause the tape to slide off indicates the adhesive’s shear resistance.

The longer the adhesive tape can hold the weight before it slides off, the better the adhesive’s resistance to shearing forces and the stickier it is deemed to be.

Tack Test

The Tack Test measures an adhesive’s immediate stickiness or tack. This is important for applications with a quick stick, such as labels or temporary seals, is necessary.

In a Tack Test, adhesive tape is quickly pressed onto a surface and immediately pulled away. The force required to pull the tape away measures the adhesive’s tack.

A higher force indicates a higher tack, meaning the adhesive can quickly form a strong bond with the surface.

Implementing an Adhesive Stickiness Test at Home

While the Peel, Shear, and Tack tests are typically conducted in a laboratory using specialized equipment, you can perform simplified versions at home to understand an adhesive’s stickiness. Here is how:

Step 1: Choose a clean, smooth, and non-porous surface for testing, like a glass panel or a cleaned stainless steel surface. Apply the adhesive tape onto this surface.

Step 2: To simulate the Peel Test at home, hold the end of the tape and start peeling it off at a 180-degree angle. Observe how much force it takes to peel off the tape. The harder it is to remove, the higher the adhesive’s peel adhesion.

Step 3: Place a small object like a paperclip or lightweight kitchen utensil at the end of the tape for a home version of the Shear Test.

Watch how long it takes for the object to slide off the tape due to its weight. The longer it takes, the higher the adhesive’s shear resistance.

Step 4: For a home version of the Tack Test, quickly touch the adhesive to the surface and then pull it away immediately. The more force it takes to pull the tape away, the higher the adhesive’s tack.

Remember, these home tests won’t provide precise measurements like laboratory tests, but they can give you a general sense of an adhesive’s stickiness.

Always conduct these tests safely, especially when dealing with heavy objects or sharp tools.

The easiest way to measure the stickiness of an adhesive is to place a small amount on your finger and then observe how well it sticks. The best way to test an adhesive’s stickiness is by applying it directly onto something you know will adhere.

To get a good read on how sticky an adhesive is, apply a thin line of it onto something like metal or glass and wait 24 hours.

The longer you wait, the less accurate your results will be since an adhesive’s stickiness will decrease slightly over time.

After 24 hours, see if any pieces have fallen off or come loose. If they did, then your adhesive isn’t very sticky at all. If everything stayed in place after 24 hours, it’s safe to say that your adhesive is quite sticky!

Factors Influencing the Stickiness of Adhesive

Understanding the factors that influence adhesive stickiness is crucial to measure it effectively.

These factors can broadly be classified into three categories: temperature effects, surface factors, and adhesive aging.

Temperature Effects

Temperature plays a significant role in adhesive stickiness. Most adhesives perform best within a specific temperature range.

Below this range, the adhesive may become brittle and lose its stickiness. Above this range, it might become too soft or even liquid, reducing its effectiveness.

Surface Factors

The surface to which the adhesive is being applied greatly affects the adhesive’s stickiness. Rough or porous surfaces can increase the contact area between the adhesive and the surface, enhancing stickiness.

On the other hand, surfaces with low energy (like plastic or Teflon) can reduce adhesion.

Aging of the Adhesive

Over time, adhesives can lose their stickiness due to oxidation, evaporation of solvents, or chemical, environmental reactions. This phenomenon is known as aging.

Last Opinion

So, there you have it! A comprehensive guide on how to measure the stickiness of adhesive.

By understanding the science of adhesion, factors influencing adhesive stickiness, and common methods to measure adhesive stickiness, you are now equipped with the knowledge to tackle adhesive-related conundrums like a pro.

Whether you’re a DIY enthusiast or just curious, understanding the stickiness of adhesives can be fascinating and practical in day-to-day life.