Are you in search of a reliable adhesive for your DIY project? Or perhaps you’re an industrial worker needing a powerful solution for mechanical assemblies?

You’ve probably heard of Loctite – a leading adhesive brand known for its diverse range of products.

By getting to know the different types of Loctite, you’ll be better equipped to choose the perfect adhesive for your needs.

Read More: Retaining Compound vs. Threadlocker

Different Types of Loctite

Loctite products, under the umbrella of Henkel Corporation, are a diverse array of adhesives designed for specific applications.

They’re celebrated for their high-quality threadlocking and thread-sealing solutions. So, let’s delve further into the various categories and particular types within these categories.

Loctite Threadlockers

Threadlockers, as the name implies, are engineered to safeguard fasteners from loosening, a common issue caused by vibrations or shock.

They accomplish this by filling the voids in the threads of metal parts, resulting in a more secure connection.

Here’s a closer examination of a few notable types:

Loctite 242 (Blue)

Often called the “blue” Loctite, this medium-strength threadlocker is a go-to for fasteners up to 3/4″ in diameter.

Its standout feature is that it permits disassembly with standard hand tools, making it a favorite for applications where regular maintenance or modifications might be needed.

Loctite 262 (Red)

The “red” Loctite, this high-strength threadlocker, is the answer for heavy-duty applications where the connection must withstand demanding conditions.

It’s crucial to note that disassembling parts secured with Loctite 262 usually requires the application of heat to break down the adhesive.

Read More: Loctite Blue vs. Red

Read More: Loctite 262 vs. 272

Loctite 222 (Purple)

The “purple” Loctite or Loctite 222 is a low-strength threadlocker. It’s best used on smaller fasteners, like those less than 1/4″ in diameter, where easy disassembly is required.

It’s favored for fine threads and delicate applications.

| Color | Strength | Ideal for | Size of Fittings |

| Blue | Medium | Applications needing regular disassembly | Up to 3/4″ |

| Red | High | Heavy-duty applications | All sizes |

| Purple | Low | Fine threads and delicate applications | Less than 1/4″ |

| White | High | High-pressure, high-temperature applications | Up to 3″ |

| Purple | Medium | Hydraulic and pneumatic systems | Up to 2″ |

In addition to these, Loctite also offers a wide range of other adhesives and sealants suitable for different materials and applications.

Loctite Thread Sealants

Loctite provides a range of thread sealants designed with unique properties to address specific demands.

Thread sealants serve a critical function in various applications. They ensure a leak-proof seal in threaded assemblies and are integral to systems carrying fluids or gases.

Thread sealants perform by effectively filling the spaces between the threads, reducing the likelihood of leaks or seepages.

Let’s look at the different thread sealants offered by Loctite.

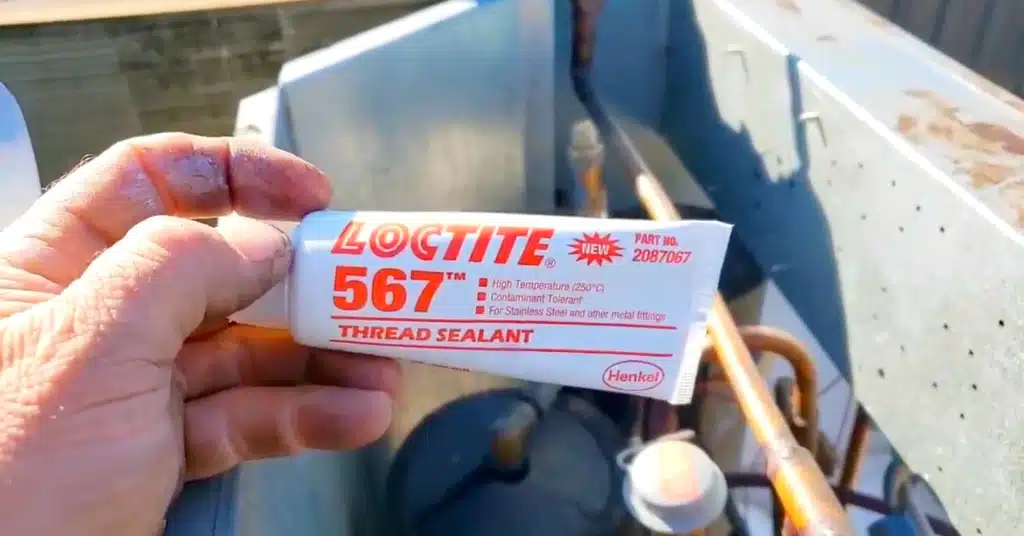

Loctite 567

Loctite 567 thread sealant is known for its excellent resistance to high temperatures, making it well-suited to challenging environments.

It can withstand temperatures up to 400°F (204°C) and resists various chemicals, preventing breakdown in harsh conditions.

This sealant’s viscosity allows it to fill tiny gaps effectively, ensuring a tight seal. It’s commonly used with stainless steel and other metal fittings in high-pressure applications.

It offers an instant, low-pressure seal and, once cured, provides a robust high-pressure seal.

Another significant feature of Loctite 567 is its ease of disassembly.

Despite a robust seal, fittings sealed with Loctite 567 can be disassembled with regular tools, a valuable characteristic during maintenance or replacements.

Read More: Loctite 565 vs. 567

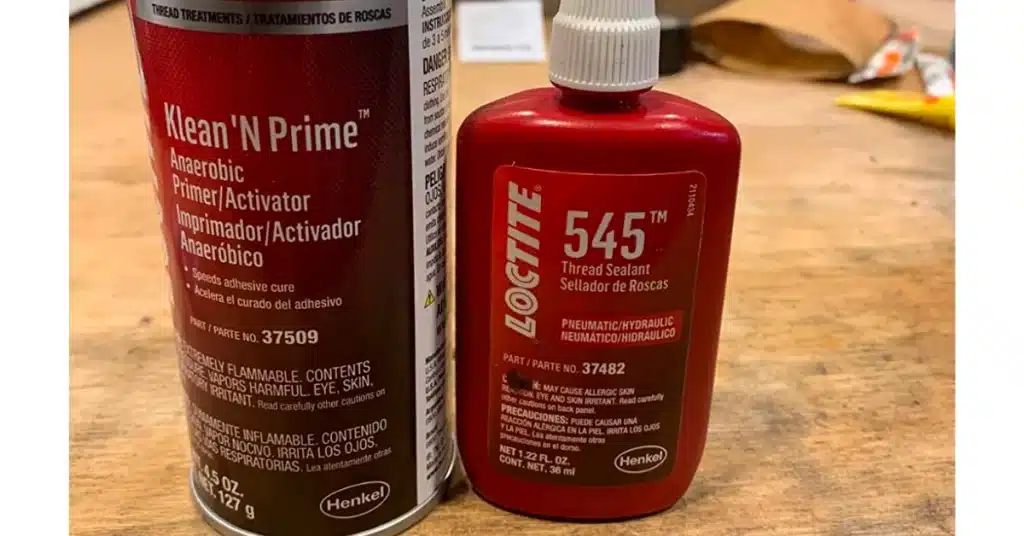

Loctite 545

Designed with hydraulic and pneumatic systems in mind, Loctite 545 is a liquid thread sealant for fine threads.

Hydraulic and pneumatic systems often operate under high pressure and require a reliable seal to prevent leaks, making Loctite 545 an ideal choice.

This sealant boasts good chemical resistance and can be exposed to various hydraulic fluids, diesel fuels, and lubricants without breaking down.

It also prevents galling, a form of wear caused by adhesion between sliding surfaces.

Loctite 545 offers an instant seal for low-pressure systems. It cures quickly, reaching full cure in just 24 hours. And, like Loctite 567, it allows for disassembly with standard tools.

Loctite 577

Loctite 577 is a general-purpose thread sealant suitable for most fittings.

It offers rapid curing, enabling quicker task completion, and can seal up to the burst pressure of most piping systems.

Resistant to fuel, oil, and hydraulic fluids, it’s a reliable choice for diverse applications.

Loctite 592

The Loctite 592 thread sealant excels in applications involving coarse threads and slow-moving parts.

This high-temperature, oil-resistant sealant is excellent for sealing against fluids, gases, and other common industrial materials.

It’s particularly useful in situations involving exposure to aggressive chemical environments.

Last Opinion

Understanding the different types of Loctite can make the difference between a job done right and a job done twice.

By considering factors like strength, temperature resistance, and the specific application, you can find the perfect Loctite product for your needs.

Remember, the right adhesive can mean the difference between a quick fix and a lasting solution. Choose wisely!

What is the difference between the different Loctites?

For instance, Loctite 222 is a low-strength threadlocker used for small screws requiring easy disassembly.

Medium-strength threadlockers like Loctite 242 and 243 are ideal for larger fasteners and can resist vibrations, yet are still removable with standard tools.

Loctite 262 and 271 are high-strength threadlockers for heavy-duty applications requiring permanent bonding. Lastly, Loctite 290, a medium to high-strength threadlocker, has unique ‘wicking’ properties for sealing pre-assembled fasteners.

Each product is designed for specific applications, temperatures, and chemical environments.

How do I choose LOCTITE?

You’ll need to consider the size of your fasteners, whether your assembly needs to be regularly disassembled, the operating conditions it will be exposed to, and the material compatibility.

The product should align with these factors. It’s always recommended to check the manufacturer’s guidelines or seek professional advice for the best choice.