In adhesives, there often needs to be more clarity around terms and their specific uses, particularly regarding Contact Cement and Contact Adhesive. While they might seem similar due to their overlapping applications, key differences must be highlighted for optimal usage.

The distinction between these two products can significantly affect your project outcome, from their compositions to the nature of their bonding capabilities.

In this guide, I will delve into the details of Contact Cement vs. Contact Adhesive. I will explore their unique properties, benefits, drawbacks, and appropriate use cases, providing a comprehensive understanding that can enhance your DIY or professional ventures.

Read More: Contact Cement vs. Gorilla Glue

Contact Cement vs. Contact Adhesive

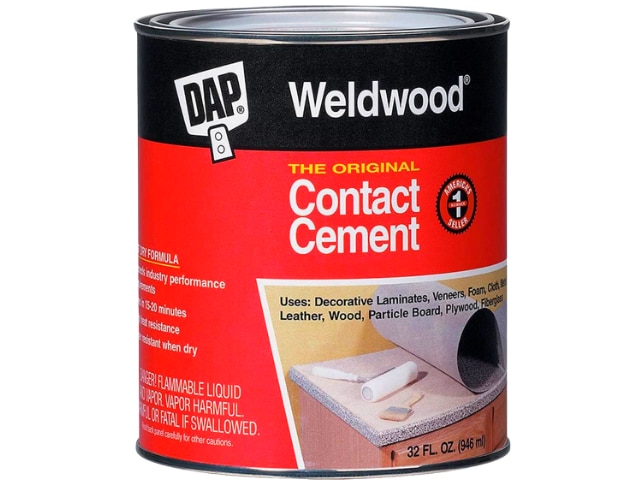

What is Contact Cement?

Contact Cement, also known as a contact adhesive, is a type of adhesive that forms an incredibly strong bond when two applied surfaces are brought together. Notable for its high initial grab, it is specifically designed to provide instant, high-strength bonds between surfaces upon contact.

Contact cement is unique in its application process compared to other adhesives. Instead of applying it to one surface, it is applied to both surfaces to be adhered. After application, the cement needs to dry until it’s no longer wet to the touch but still tacky. At this point, the two surfaces can be pressed together to create a durable bond.

It’s a versatile adhesive that can be used with a wide range of materials, such as laminates, veneers, rubber, cork, and leather, to name a few. It’s particularly popular in woodworking and home improvement projects, often used to attach laminate to countertops or cabinets. The bond it forms is very tough and can resist heat, water, and many types of wear and tear.

However, working with contact cement requires precision. Once the two surfaces touch, they cannot be adjusted. This, along with the strong fumes it often produces, requires careful application and adequate ventilation when using this adhesive.

What is Contact Adhesive?

Contact adhesive, often confused with contact cement due to their similar properties and applications, is designed to form strong, durable bonds between various surfaces. It’s widely used in various projects and industries due to its versatility and high bonding strength.

Like contact cement, contact adhesive is applied to both surfaces that must be joined. After application, it’s typically left to dry to a tacky state, and the two surfaces are pressed together. This results in an immediate and robust bond highly resistant to water, temperature variations, and wear and tear. It can be used on various materials, including plastics, metal, wood, and foam.

However, despite the general similarities, not all contact adhesives are created equal. They can vary based on their specific formulations, including different polymers, solvents, and additives. This can affect their bonding strength, drying time, and resistance to environmental factors. For instance, some contact adhesives may be designed for indoor use only, while others might also be suitable for outdoor applications.

Like with contact cement, working with contact adhesives requires precision because they cannot be repositioned once the surfaces are joined. Also, due to the potentially strong fumes produced during the application, it’s advisable to use contact adhesives in a well-ventilated space and with appropriate safety gear.

What is the Difference Between Contact Adhesive and Contact Cement?

While Contact Adhesive and Contact Cement are often used interchangeably due to their similar properties and applications, subtle differences can impact their usage in different scenarios.

- Composition: Both are made from various chemicals, but they can have different formulations. Contact cement is often rubber-based, providing a flexible yet durable bond. In contrast, contact adhesives might use different polymers and additives, which can influence their bonding strength, drying time, and environmental resistance.

- Application Range: Both adhesives can be used on various materials, but certain contact adhesives might work better on specific materials. For example, some are better suited for plastic or metal, while others may be ideal for foam or fabrics. Contact cement, on the other hand, is widely used in woodworking and for attaching laminate to various surfaces.

- Curing Time: Depending on the specific formulation, the curing or drying time can vary between these adhesives. Some contact adhesives may require longer drying times than contact cement.

- Adjustability: Typically, both adhesives form an instant bond that doesn’t allow repositioning. However, some contact adhesives may offer a limited ability to reposition materials after the initial contact, unlike contact cement.

- Temperature Resistance: While both adhesives generally provide good resistance to temperature variations, certain contact adhesives might perform better in extreme conditions, depending on their specific formulation.

Read More: Spray Adhesive vs. Contact Adhesive

Advantages of Contact Cement

Contact Cement is a versatile adhesive, favored by many professionals and DIY enthusiasts alike for its unique qualities. Here are some of the key advantages of using Contact Cement:

- Strong Bond: Contact cement is known for creating a highly durable and robust bond between surfaces. It forms an instant, high-strength bond that is resistant to wear and tear, making it ideal for applications that require durability.

- Versatility: It can be used with a wide array of materials, such as laminate, veneer, leather, rubber, and more. This makes it a go-to adhesive for many different types of projects, from woodworking to home improvement tasks.

- Heat and Water Resistance: The bond formed by contact cement is resistant to both heat and water, making it suitable for use in various environmental conditions. It’s particularly helpful in areas that may be exposed to moisture or high temperatures.

- Flexible: Despite its strength, contact cement allows for some flexibility, which can be beneficial when working with materials that might expand, contract, or otherwise move.

- Fast-Drying: Contact cement typically dries quickly, which can help speed up project completion times. This can be particularly useful in professional settings where efficiency is critical.

- Coverage: A small amount of contact cement can cover a large area, making it a cost-effective choice for larger projects.

Advantages of Contact Adhesive

Contact Adhesive have some advantages and disadvantages too. Since contact adhesive is flexible and pressure-sensitive, it can be used to bond a variety of materials. And because it doesn’t permanently bond two surfaces together, you can easily remove items from your walls without damaging them.

Plus, contact adhesives don’t have an extended curing time—they’re usually ready for use within minutes or hours after application. These are just a few reasons professional interior designers prefer using contact adhesives.

What Can I use instead of Contact Cement?

Glue dots and spray adhesive – If you’re looking for an adhesive that doesn’t require clamping, these two types might be good alternatives.

What is Contact Adhesive Used for?

How Long Does Contact Cement Last?

The glue is usually clear or white in color and should not be confused with other adhesives sold under similar names (such as Super Glue).

It’s important to remember that using too much contact cement can make it impossible to remove from your hands and tools, so you should always use just enough for your project.

Last Opinion

For small projects, contact cement is generally easier to use and safer for indoor work that won’t get a lot of foot traffic; however, it won’t stand up to heavy wear and tear or extremes in temperature.

In these situations, contact adhesive is best—but you’ll want to test its bonding capabilities on any surfaces before using it permanently on a project.