Conductive Glue and Solder are two adhesives commonly used on electrical components.

However, you might get confused when it comes to which one you should buy for your specific needs.

I have discussed Conductive Glue vs. Solder and pointed out their core differences so you know which fits your needs best.

Read below before making a decision.

Read More: QuietRock Vs. Green Glue

Conductive Glue vs. Solder

What Is Conductive Glue?

Conductive glue, also known as electrically conductive adhesive, is a special type of glue used for electronics. This adhesive contains conductive particles in its composition to provide exceptional electric conductivity during bonding.

Being an excellent conductor of heat, this adhesive is used to join electronic components together without soldering or mechanical fasteners.

And as it is an incredible conductor of electricity, this glue allows electrical current to flow between the surfaces without any difficulties.

Also, as it is a mix of conductive particles with high-strength adhesive, a Conductive Glue offers improved reliability and durability when boing components.

What Is Solder?

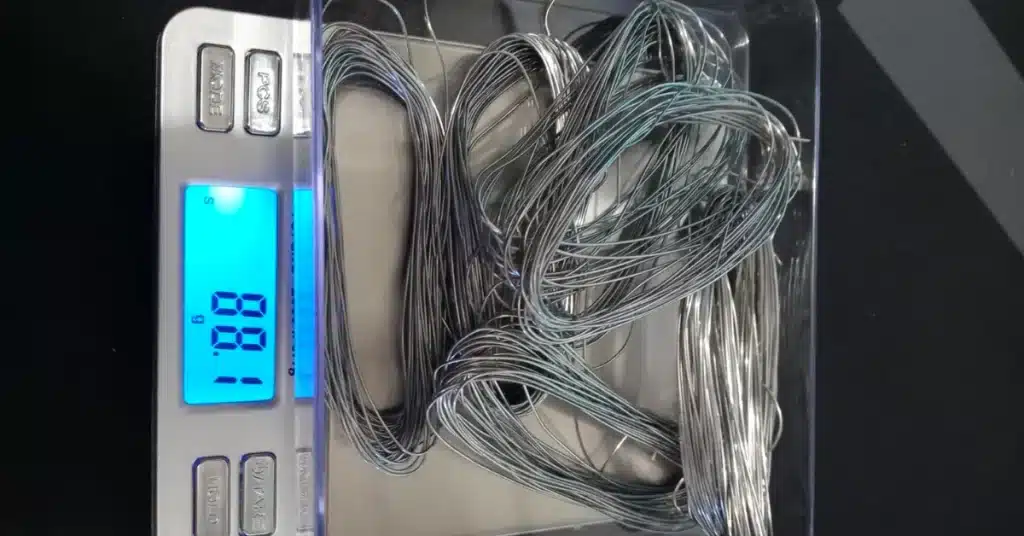

Solder is a metallic alloy used to permanently join metal components efficiently. As this special type of adhesive has a relatively low melting point, it melts quickly to join the metal components without affecting the surfaces.

Made from a mixture of low-melting metals, this adhesive flow along the surfaces of the materials to create an incredibly strong bond.

It doesn’t matter if you use it on electronics, wiring, plumbing, jewelry making, or other industrial things; Solder provides a reliable and permanent bond that lasts for a long.

Comparison Table

I have listed all the significant differences between Conductive Glue and Solder for you. Go through these differences for a quick look.

| Features | Conductive Glue | Solder |

| Product Form | Liquid Adhesive | Metal Wire |

| Composition | Mix of conductive particles and adhesive | Mix of tin and lead alloy |

| Bonding Mechanism | Adhesive bonding | Metal bonding |

| Bonding Strength | Moderate | Incredibly strong |

| Heat Conductivity | Moderate | High |

| Safety | Safe to use | Might impose health risks |

Differences Between Conductive Glue and Solder

Here is an in-depth discussion of the differences between Conductive Glue and Solder for even more information.

Product Form

One major difference between Conductive Glue and Solder is in their product form.

Conductive Glue is a liquid adhesive with conductive particles in it. While the conductive particles ensure the electrical conductivity between the joined components, the liquid form makes it super easy and fuss-free to apply.

On the other hand, Solder is made from metal alloy and comes in a solid “wire” form. You need to melt it at a low temperature to join the metal surface together.

As you need electricity and a soldering wand to melt and use Solder, it might seem a little difficult to use.

Bonding Mechanism

The bonding mechanism of both Conductive Glue and Solder is very interesting.

For instance, as Conductive Glue comes in a liquid adhesive form, they provide adhesive bonding on the surfaces.

However, as this adhesive isn’t as strong and offers moderate bonding, it might get affected by vibrations and mechanical stress.

But the same isn’t true for Solder. Because of its metallic construction, it provides metal bonding and ensures superior strength.

As it joins surfaces by melting metal, it creates a robust bonding between the surfaces.

Safety

Safety is yet another crucial difference between Conductive Glue and Solder.

Because Conductive Glue comes in a liquid form, it is easy to apply on surfaces without the need for any specialized equipment.

But, the case with Solder is completely different. You need to be extremely careful while using it because it requires skill and a soldering wand for bonding.

Without proper skillsets and safety measures, you might end up hurting yourself while using this metal adhesive.

Last Opinion

The comparison of Conductive Glue vs. Solder above is very thorough and easy to understand. I have discussed all the significant differences between these two adhesives so that you can determine which one you need for your specific needs.

As both these adhesives are very different, with different properties and application processes, choose the one according to your requirements as well as your skillsets too.