Knot holes in wood can be both a beautiful and challenging aspect of woodworking. They add character to the finished product, but they also require proper treatment to ensure the integrity and longevity of the piece. One popular method for filling knot holes is using epoxy resin.

In this article, I’ll explore the best epoxy for filling knot holes, discuss their advantages, and provide a step-by-step guide to help you achieve a professional finish.

Read More: Best Epoxy For Basement Floor

What are Knot Holes?

Knot holes are natural imperfections found in wood, created when tree branches grow, and are subsequently cut off during lumber production. These holes can vary in size, shape, and depth.

Why Knot Holes Need Filling?

Filling knot holes is important for several reasons:

- To prevent dirt, dust, and moisture from accumulating in the hole, which could lead to decay or rot.

- To provide a smooth, even surface for finishing.

- To enhance the wood’s structural integrity and stability.

Best Epoxy for Filling Knot Holes

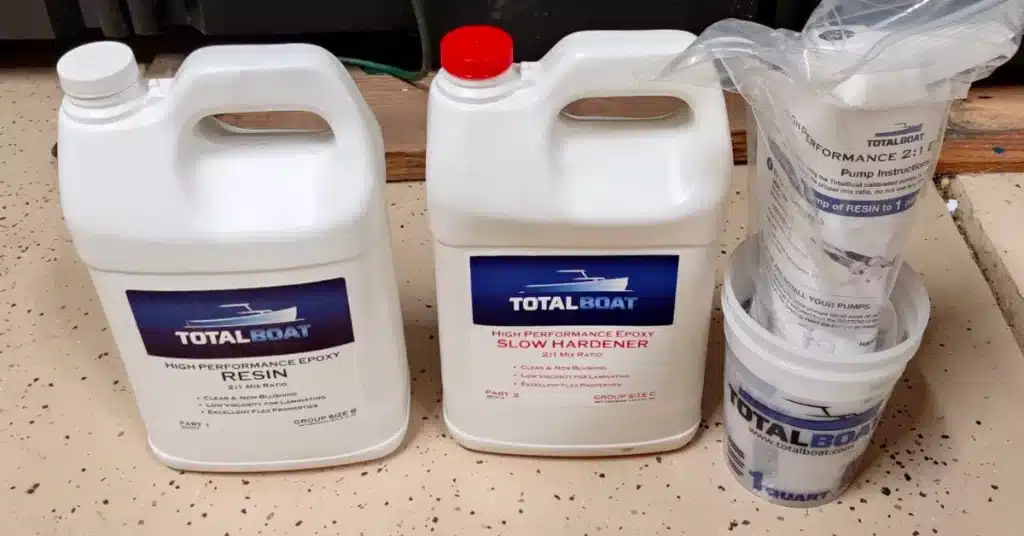

TotalBoat High-Performance Epoxy

First off, what exactly is TotalBoat High-Performance Epoxy? In a nutshell, it’s a two-part epoxy system designed to cater to a wide range of applications, from boat building and repair to woodworking, arts, and crafts. But what makes it stand out from the crowd? Let’s break it down.

Ease of Use: Who doesn’t love a product that’s user-friendly, right? TotalBoat High-Performance Epoxy is incredibly easy to mix, with a simple 2:1 ratio of resin to hardener. This means you won’t waste precious time fiddling with measurements and calculations. Plus, it’s self-leveling, so you’ll get a smooth, even finish every time.

Strength and Durability: When it comes to epoxy, you want something that’ll hold up under pressure and last the test of time. TotalBoat High-Performance Epoxy delivers on this front, providing a bond that is strong and resistant to moisture, heat, and chemicals. What more could you ask for?

Versatility: As mentioned earlier, TotalBoat High-Performance Epoxy is suitable for various applications. Whether you’re working on a boat, creating a stunning piece of furniture, or crafting a one-of-a-kind art piece, this epoxy has got you covered.

Clear and Non-Blushing: A clear epoxy that doesn’t blush? Yes, please! TotalBoat High-Performance Epoxy dries clear, allowing the beauty of your project to shine through. Moreover, its non-blushing formula means you won’t have to deal with those pesky white spots that can sometimes appear on the surface.

So, does TotalBoat High-Performance Epoxy live up to the hype? Based on the features we’ve discussed, it seems that way. But, as with any product, it’s also important to consider the downsides.

One potential drawback is the price – this high-quality epoxy might not be the most budget-friendly option on the market. However, considering its benefits, many users might find it worth the investment.

Read More: 1 Part vs. 2 Part Epoxy

EcoPoxy Liquid Plastic

EcoPoxy Liquid Plastic is a two-part epoxy resin system specifically designed for various applications, from woodworking and river tables to art projects and jewelry making. But what sets it apart from other epoxy resins on the market? Let’s discuss some of its key features:

Environmentally Friendly: As the name suggests, EcoPoxy Liquid Plastic is all about being eco-friendly. It’s formulated using bio-based materials and boasts a low VOC content, making it a greener alternative to traditional epoxy resins. Plus, it’s non-toxic and odorless so that you can work in a safer, more pleasant environment.

Crystal Clear and UV Resistant: One of the most important aspects of epoxy resin is its clarity. EcoPoxy Liquid Plastic delivers on this front, curing to a crystal-clear, high-gloss finish that allows the beauty of your project to shine through. Additionally, it has built-in UV resistance, which helps prevent yellowing and protects your work from sun damage.

Easy to Use and Versatile: EcoPoxy Liquid Plastic features a straightforward 2:1 mixing ratio of resin to hardener, making it a breeze to mix and apply. Its extended working time of up to 72 hours allows you to perfect your project without feeling rushed. And with its versatility, you can use EcoPoxy for various applications, from casting to coating.

Low Shrinkage and Self-Leveling: Nobody wants an epoxy resin that shrinks and warps as it cures. EcoPoxy Liquid Plastic ensures minimal shrinkage, maintaining the integrity of your project. Its self-leveling properties make it easy to achieve a smooth, even finish.

As with any product, it’s essential to consider the potential downsides. One drawback of EcoPoxy Liquid Plastic is its longer curing time than other epoxy resins. This means you may need to wait longer before your project is fully cured and ready to use. However, the eco-friendly and non-toxic benefits may outweigh this inconvenience for many users.

ArtResin Epoxy Resin

First and foremost, what is ArtResin Epoxy Resin? Simply put, it’s a high-quality, two-part epoxy resin system designed for artists and crafters. It promises a crystal-clear, glossy finish that enhances and preserves your artwork. But what sets ArtResin apart from other epoxy resins on the market? Let’s break it down:

Non-Toxic and Safe: Safety should always be a top priority when working with epoxy resins. Thankfully, ArtResin Epoxy Resin is formulated to be non-toxic and safe for artists. It’s BPA-free and contains no VOCs or fumes, so you can work with peace of mind, knowing that you and your surroundings are protected.

Easy to Use: Let’s face it, nobody wants to struggle with a complicated epoxy system. ArtResin Epoxy Resin is incredibly user-friendly, with an easy 1:1 mixing ratio of resin to hardener. Plus, its 45-minute working time ensures you have ample opportunity to perfect your masterpiece.

UV Protection: One of the most significant concerns for artists is the dreaded yellowing that can occur over time. Fear not! ArtResin Epoxy Resin has built-in UV stabilizers that prevent yellowing and protect your artwork from the harmful effects of sunlight. Talk about a win-win!

Self-Leveling and Bubble-Free: Achieving a smooth, even finish is a breeze with ArtResin Epoxy Resin. Its self-leveling formula ensures a consistent coating and has excellent bubble-release properties, leaving your artwork with a flawless, glass-like surface.

Of course, no product is without its drawbacks. While ArtResin Epoxy Resin has many outstanding features, it’s worth noting that it’s on the pricier side than other epoxy resins. However, many artists find the quality and safety of ArtResin worth the extra cost.

Crystal Clear Bar Table Top Epoxy Resin

Crystal Clear Bar Table Top Epoxy Resin is a two-part epoxy resin system specifically designed for coating and sealing surfaces like tabletops, countertops, and bar tops. But what sets it apart from other epoxy resins on the market? Let’s delve into its key features:

Crystal Clear and High-Gloss: When it comes to coating surfaces, clarity, and shine are crucial. Crystal Clear Bar Table Top Epoxy Resin delivers on both, curing to a stunning, high-gloss finish that showcases the beauty of your project without any distracting blemishes or yellowing.

UV Resistant: Over time, exposure to sunlight can wreak havoc on surfaces, causing discoloration and damage. Thankfully, Crystal Clear Bar Table Top Epoxy Resin has UV resistance, which helps prevent yellowing and protects your surfaces from sun-induced degradation.

Easy to Use: People want to avoid fiddle with a complicated epoxy system, right? Crystal Clear Bar Table Top Epoxy Resin is designed to be user-friendly, featuring a 1:1 mixing ratio of resin to hardener, and a self-leveling formula that makes achieving a smooth, even finish a breeze.

Water and Scratch Resistant: Durability is key for surfaces that see a lot of use. Crystal Clear Bar Table Top Epoxy Resin offers excellent water resistance, perfecting kitchens, bars, and other wet environments. Additionally, it’s resistant to scratching, ensuring your surfaces look their best even with heavy use.

While Crystal Clear Bar Table Top Epoxy Resin offers many fantastic features, it’s essential to consider potential drawbacks. One downside is its sensitivity to temperature during curing. This means you’ll need to ensure a controlled environment for the best results, which may be challenging for some users. Also, as with many epoxy resins, it can be pricier. However, many users find the investment worthwhile for its stunning results.

MAS Deep Pour Epoxy

MAS Deep Pour Epoxy is a two-part epoxy resin system specially formulated for deep pour applications, such as river tables, live edge slabs, casting, and encapsulation. But what makes it stand out from other epoxy resins on the market? Let’s discuss some of its key features:

Designed for Deep Pours: One of the main selling points of MAS Deep Pour Epoxy is its ability to be poured up to 2 inches deep in a single pass. This allows for seamless, bubble-free results and eliminates the need for multiple pours, saving time and effort.

Extended Working Time: Having ample time to perfect your project is crucial when working with epoxy. MAS Deep Pour Epoxy offers an extended working time of up to 20 hours, allowing you to take your time and ensure everything is right.

Crystal Clear and UV Resistant: When it comes to epoxy resin, clarity is key. MAS Deep Pour Epoxy cures to a crystal-clear, high-gloss finish, allowing the natural beauty of your project to shine through. Additionally, it’s UV resistant, which helps protect your work from yellowing and sun damage.

Low Exothermic Reaction: One concern with deep-pour epoxy resins is the heat generated during curing. Thankfully, MAS Deep Pour Epoxy has a low exothermic reaction, producing less heat while curing, reducing the risk of cracks and other defects in your project.

One drawback of MAS Deep Pour Epoxy is its relatively longer curing time than other epoxy resins. This means you may need to wait longer for your project to cure and be ready for use fully. Additionally, it may be on the pricier side for some users. However, the benefits of a seamless, deep pour may outweigh these inconveniences for many.

Advantages of Using Epoxy for Filling Knot Holes

Epoxy has several benefits when used for filling knot holes:

- It creates a strong, long-lasting bond.

- It’s moisture-resistant, making it suitable for indoor and outdoor applications.

- It can be tinted or dyed to match the surrounding wood.

- It dries clear, allowing the natural beauty of the wood to shine through.

Safety Tips for Working with Epoxy Resin

- Work in a well-ventilated area.

- Wear protective gloves and eyewear.

- Follow the manufacturer’s instructions for mixing and curing times.

- Store epoxy resins and hardeners in a cool, dry place away from direct sunlight.

Last Opinion

Filling knot holes with epoxy resin effectively enhances the beauty and structural integrity of your woodworking projects.

By selecting the right epoxy for your needs and following the proper techniques, you can achieve a professional, long-lasting finish that showcases the natural beauty of the wood.

Remember always to work safely and responsibly when handling epoxy resins.