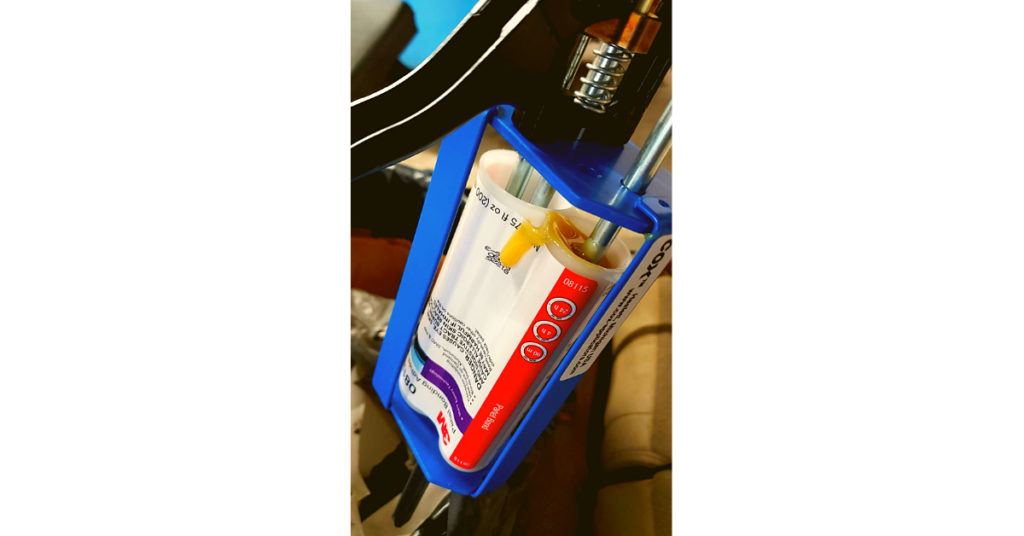

When it’s about the same kind of glues like 3M 08115 and 08116, you need to figure out the differences first to choose the better one. Get information about 3M 08115 vs. 08116 to know everything about them.

Both epoxies have the same type of features. They are two-part panel bonding adhesives. They are good for roof skins, quarter panels, box sides, door skins, and more. The 08115 is the faster one, and the 08116 is the stronger one.

To know more about the products well, get through the 3M 08115 vs. 08116 comparisons, then choose accordingly.

Read More: Panel Bonding Adhesive Vs. Welding

3M 08115 Vs. 08116

What Is 3M 08115 Adhesive?

The 3M 08115 adhesive is a two-part epoxy with several features for a smooth working system. The professional grade epoxy provides a fast cure outcome.

It offers extended work time and a fast curing facility with heat. Also, the OEM recommends this glue. So, you can get an excellent adhesion on the free materials if you use them properly.

In terms of versatility, this epoxy can be used for various purposes. You can use it to bond door skins, box sides, roof skins, quarter panels, bumper covers, and more.

Another good thing about this glue is it has glass bead technology. It protects the material from over-clamping.

Also, it can maintain the minimum bond line thickness. You get two static mixing nozzles that are good for precise application.

So, for a professional finish, get this glue and use it as instructed to have the strongest adhesion.

What Is 3M 08116 Adhesive?

The 3M 08116 is also a two-part panel bonding adhesive. Many OEMs recommend it, and it has a professional-grade finish. You can use this epoxy adhesive on multiple materials like metal, plastic, glass, aluminum, and steel.

To get a professional-grade finish, this 3M 08116 glue is the best. It can work fast under heat, which is a good sign. You can get an extended work time so that you can save time.

The epoxy is suitable for use on various metal and plastic objects. Besides, it can bond roof and door skins, box sides, quarter panels, bumper covers, and more.

It also has glass bead technology that maintains a minimum bond line thickness and protects against over-clamping. You can also get two static mixing nozzles to have a precise application.

Overall, it is a great deal to work with this 3M 08116 glue.

Read More: How To Use 3M Panel Bonding Adhesive?

What Is The Difference Between 3M 08115 And 08116 Adhesives?

The 3M 08115 and 08116 adhesives are almost identical in features, working processes, etc. Both are two-panel bonding adhesives. They can handle heat well as it contains glass bead technology.

Also, it can ensure a minimum bond line thickness. So, you cannot squeeze out all the product if you need it for over-clamping. Moreover, they have corrosion inhibitors.

However, there are some differences between these two products. The 08116 epoxy is specifically designed to meet General Motors and Chrysler specifications.

It maintains better corrosion protection for many years. When it’s about 3M 08115 glue, it has a shorter clamping time than the 08116 one.

Both types of glue are used for outer body panels. To figure out which one is the better one, you must follow the OEM recommendations.

What is 3m 8115 used for?

Which adhesive is better?

How long does 3M 08115 take to work?

Last Opinion

Now that you know the difference between the glues, you can figure out the better one for your job. If you want a faster curing epoxy, go for the 08115 one.

And if you want stronger adhesion with better technology, you can use the 08116 epoxy. Choose what suits your job and preference.

Get through all about 3M 08115 vs. 08116 epoxies, and hopefully, you get the desired results that you wish for.