Adhesives are used in packaging for all sorts of reasons, from keeping the package closed to improving the shelf life of the contents inside. When you’re looking to buy adhesives, there are many types to choose from, and each one has its own purpose and special use cases. Here are five most popular types of adhesives used in packaging.

5 Types of Adhesives Used in Packaging

1) Pressure Sensitive Adhesive

Pressure sensitive adhesives, also known as PSAs, are used to stick labels onto flat surfaces, such as boxes and cans. They’re most often formulated with acrylics.

Pressure sensitive adhesives require a good amount of surface contact, which is why they’re common on packaging; they usually have a shelf life longer than three years.

An added bonus: these kinds of glue don’t leave any residue when applied correctly. If you’re not quite sure what goes into pressure sensitive adhesives or would like to compare them with other types, check out our PSA guide at PCA Magazine for further details and resources!

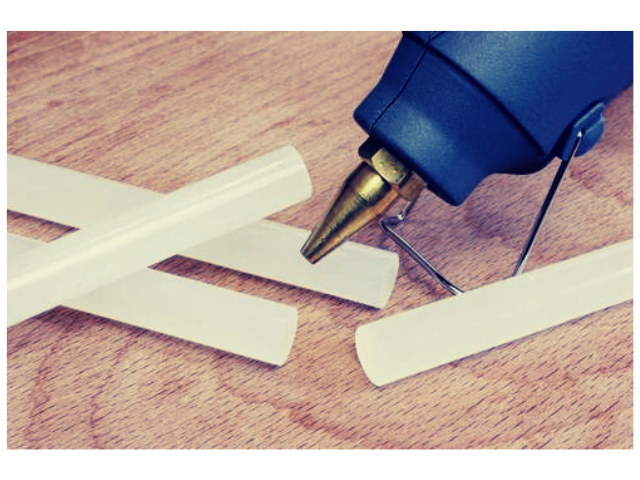

2) Hot Melt Adhesive

Hot melt adhesives are viscous liquids that turn into a solid when heated. The two most common varieties are thermoplastic and thermoset adhesives.

Thermoplastic hot melts can be remelted and reused, making them both cost-effective and easy to use.

Thermoset hot melts, which cannot be remelted, produce permanent bonds; however, they can be difficult to remove from packaging equipment after use.

Hot melt adhesives are widely used in plastic films and sheets to secure labels, bond sheets or films together, or attach films to paperboard boxes.

They’re also widely used in food packaging because they have good moisture resistance; you may find these adhesives on labels on cans of baked beans or soup.

3) Water-based Adhesive

This is a classic choice for packaging adhesives, as it is often less expensive than other options. These adhesives are environmentally friendly, easy to clean up, and create strong bonds.

The downside to water-based adhesives is that they can leave residue when dry. If you have printed materials with text or photos on them, water-based adhesive may not be your best choice for package sealing tape.

Additionally, these adhesives often require some time to set before stacking or closing boxes. If time is limited, adhesive tapes that dry more quickly might be a better fit for your project needs.

Read More: Types of Cement Adhesive

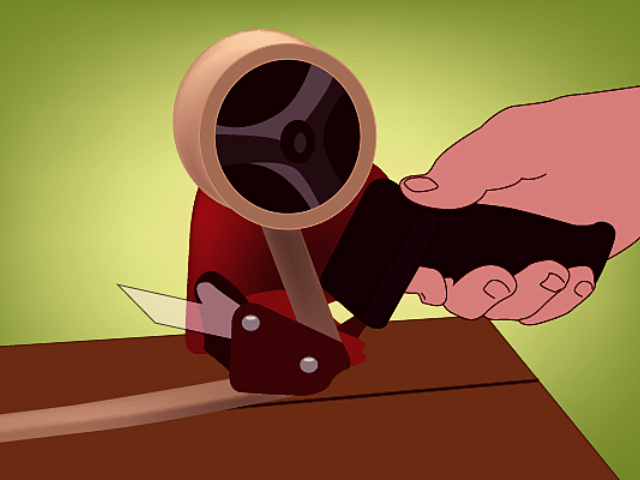

4) Tape Dispenser

In modern day workplaces and organizations, tape dispensers are found more often than not. Tape dispensers provide a quick and easy way to dispense tape with minimal effort on behalf of your employees or company workers.

However, there are various kinds of tape dispensers that can be used for different types of materials such as plastic tapes, paper tapes, fiberglass tapes and so on.

If you’re looking for a reliable and cost-effective solution to dealing with your tape issues, it’s recommended that you consider purchasing an industrial grade quality tape dispenser that will last over time and can be used for multiple purposes.

5) Spray Adhesive

These are liquids that turn into glues when sprayed or brushed onto surfaces. You can get them to stick just about anything, but they aren’t good for creating airtight seals and are messy to work with.

Think: You might want to use spray adhesive to secure invitations, wrapping paper or other items that need a little bit of help staying together. Keep in mind that even though they’re pretty easy to use, some don’t dry clear and are water-soluble; so read all instructions carefully before applying them.

When it comes time to remove an item stuck down with spray adhesive, soak it with warm water (not boiling) for about 10 minutes. The stickyness will dissolve and you can easily slide off any residue left behind.

Read More: Types of Adhesives Used in Construction

Last Opinion

Which one is better for your packaging needs? It really depends on your situation. All five adhesives are effective; it’s just a matter of what will work best for you. To summarize, here are some things to keep in mind when selecting an adhesive:

1) Formulation – A number of different components can go into manufacturing an adhesive, each with its own set of pros and cons. It’s important to understand which ones might be right for your specific application.

2) Performance characteristics – Each type has its own set of performance characteristics (e.g., tack, adhesion strength, ease/speed of use).

3) Product costs – While prices depend on a number of factors such as volume and distributor relationships, they can range widely between these options. Some types of adhesives may also require special equipment to apply. If this applies to you, make sure that the cost of the equipment does not exceed the savings from using the cheaper option.

For example, if two adhesives are similar in price but only one requires expensive machinery, then it would be more prudent to purchase the adhesive that doesn’t need special tools.

The most common types of adhesives are hot melt adhesive, acrylic glue, contact cement, solvent-based glue and epoxy.

In summary, it’s wise to do your research so that you can find the best option for your situation.