The Loctite 620 and Loctite 680 high-strength retaining compounds are the most popular choices for bonding cylindrical parts to metal substrates. When it comes to choosing between Loctite 620 and 680, there are a few key differences to consider.

Loctite 620 is a high-strength, high-viscosity adhesive that is ideal for bonding cylindrical parts such as bearings and bushings. On the other hand, Loctite 680 is a low-viscosity adhesive that is designed for bonding close-fitting parts such as gearboxes and valve housings.

Here, I will compare Loctite 620 Vs. 680, to conclude the battle between them.

Read More: Loctite 609 vs. 680

Loctite 620 Vs. 680

Overview of Loctite 620

Loctite 620 is a green glue that is very strong and can handle high heat. For applications requiring strong, permanent bonds between cylindrical parts, it is a popular choice. It stops them from moving or leaking when they shake or hit something.

It is good for things that get very hot, like pins in radiators, sleeves in pumps, and bearings in cars. It takes 60 minutes to stick and 24 hours to dry completely.

Its high viscosity allows it to fill gaps and prevent leaks, while its longer curing time provides ample time for adjustments before the bond sets.

Read More: Loctite 542 Vs. 545

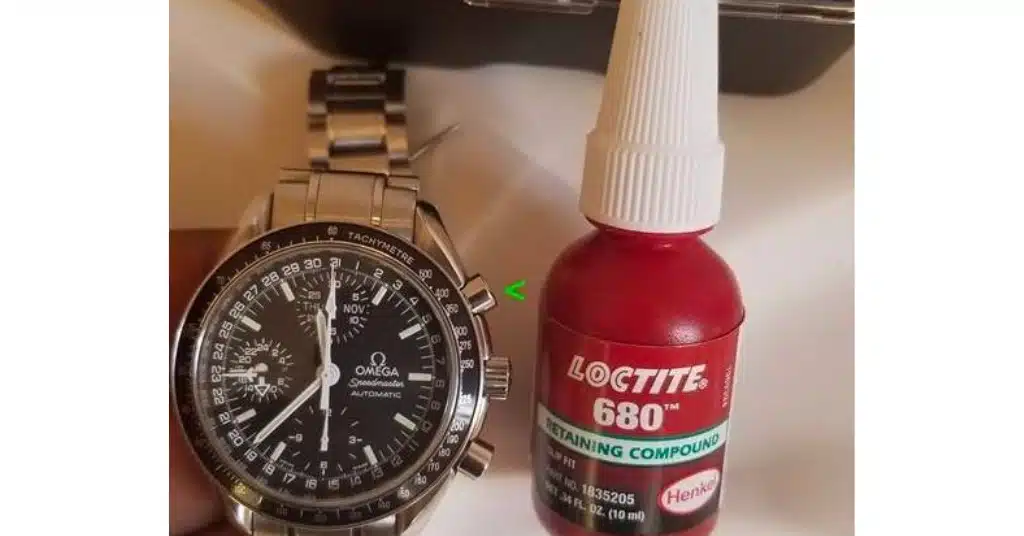

Overview of Loctite 680

Loctite 680 is also a green, high-strength retaining compound that cures anaerobically between metal surfaces. It is specially formulated for the bonding of loose-fitting parts, such as worn shafts and housings.

Heavy machinery and equipment use the adhesive because it resists stress, vibration, and temperature changes. It is oil tolerant, primerless, and fluorescent for easy inspection.

It has a fixture time of 4 minutes and a full cure time that depends on the substrate and temperature.

Read More: Loctite 638 vs. 680

Comparison Between Loctite 620 and Loctite 680

| Feature | Loctite 620 | Loctite 680 |

| Physical form | Liquid | Liquid |

| Application Method | Dispense system, manual | Dispense system, manual, pressure |

| Applications | For high-temperature applications, for slip-fitted parts, retaining | For loose fitting parts, for slip-fitted parts, retaining |

| Viscosity | High viscosity | Low viscosity |

| Fixture time | 60 min | 4 min |

| Shear strength | 3800 psi | 4000 psi |

| Cure type | Anaerobic cure | Anaerobic cure |

Which One To Use? Loctite 620 or Loctite 680?

This depends on the application and requirements of your project. Loctite 620 and 680 are both retaining compounds that are used to bond cylindrical parts such as bearings, bushings, and gears. They work when there is no air and metal around them.

Loctite 620 is good for metal things only, while Loctite 680 can work with metal, plastic, and rubber things too.

Loctite 620 is also good for things that get very hot, like pins in radiators, sleeves in pumps, and bearings in cars. It is perfect for metal things that fit well together and need a strong and heat-proof bond.

Loctite 680 is more suitable for loose-fitting parts, such as worn shafts and housings. It is ideal for metal parts that are loose or worn out and need a fast and easy bond.

Therefore, you should use Loctite 620 if you need a high-temperature resistance, high strength, and a good gap filling for close-fitting parts.

You should use Loctite 680 if you need a fast cure speed, a low viscosity, and an easy inspection for loose-fitting parts.

Can Loctite 620 Be Removed?

Yes, Loctite 620 can be removed. One way to remove it is by applying heat with a heat gun.

Is Loctite 680 Permanent?

Yes. Loctite 680 secures metal fasteners permanently.

How strong is 680 Loctite?

Loctite 680 is a very high strength retaining compound. It provides a shear strength of 4,000 psi.

Last Opinion

Loctite 620 and Loctite 680 are both high-strength adhesives that offer excellent bonding capabilities for metals.

However, Loctite 680 is specifically designed for use on cylindrical parts and can fill gaps up to 0.25mm, while Loctite 620 is ideal for bonding flat surfaces and can fill gaps up to 0.5mm.

Hopefully this article has helped you compare Loctite 620 vs. 680 and make an informed decision.