The purpose of waterproofing your home or building is to keep it safe from water damage and to prevent mold and mildew growth. Drylok and Flex Seal are two popular waterproofing products.

In spite of the fact that both products are highly effective in their own way, they differ in terms of their applications, uses, and effectiveness in different ways.

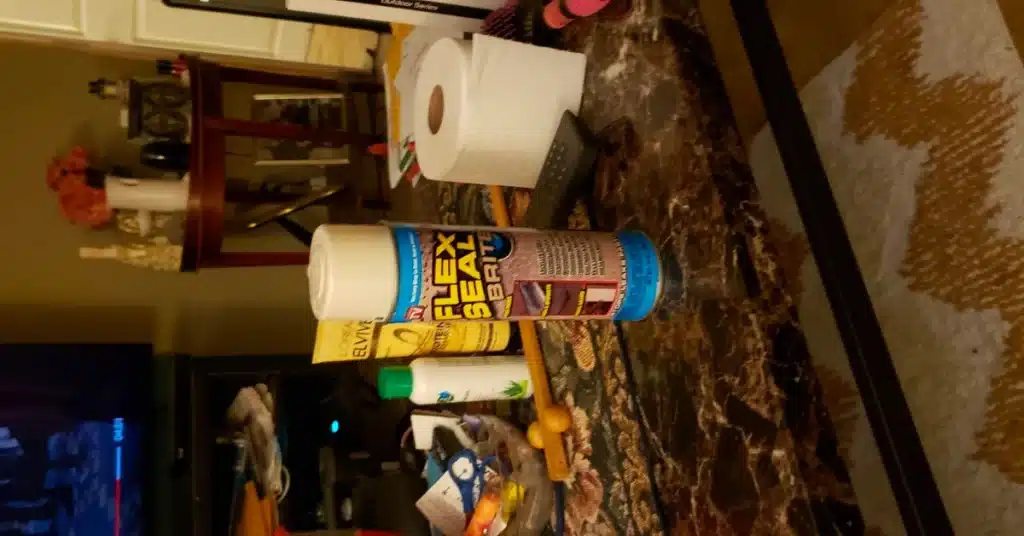

Flex Seal is suitable for sealing cracks and leaks in a wide range of surfaces, while Drylok prevents water penetration into masonry surfaces.

In this article, I will compare drylok vs flex seal so that you can decide which is best for your waterproofing needs.

Read More: Flex Seal Vs. Rust-Oleum LeakSeal

Read More: Rubber Flexx Vs. Flex Seal

Drylok Vs. Flex Seal

Overview of Drylok

Drylok is a waterproofing paint designed for masonry surfaces, such as basement walls, foundations, or retaining walls.

It is a water-based coating that penetrates the pores of the masonry surface to prevent water from penetrating. Several colors of Drylok are available, and this paint can be painted over with any latex or oil-based paint.

You can apply Drylok with a brush, roller, or sprayer. After drying, it provides an excellent base for painting. While Drylok is effective at preventing water penetration, it is not recommended for sealing leaks or cracks in areas with heavy water pressure.

Overview of Flex Seal

Flex Seal is a rubberized coating created to seal leaks and cracks in metal, wood, concrete, and plastic. A leak or crack in a roof, gutter, pipe or other surfaces can be sealed with this sealant. It is available as a spray can or a liquid that can be brushed or rolled on. It dries to a rubbery, flexible finish that is waterproof and UV-resistant.

Flex Seal can be applied to both dry and wet surfaces. When water pressure is moderate to low, it is ideal for sealing leaks or cracks.

Despite its waterproofing properties, Flex Seal should not be used on masonry surfaces or areas with high water pressure.

Read More: Flex Seal Tape Vs. Gorilla Tape

Comparison Between Drylok and Flex Seal

In deciding between Drylok and Flex Seal, you should consider the type of surface, the type of water pressure, and the extent of the damage. Here are some key factors to consider:

Application Method: Drylok is typically applied with a brush, roller, or sprayer, while Flex Seal comes in a spray can or a liquid that can be brushed or rolled on.

Surface Type: Drylok is designed for use on masonry surfaces, while Flex Seal can be used on metal, wood, concrete, and plastic surfaces.

Water Pressure: Drylok can be used in areas with low to moderate water pressure. Low- to moderate-pressure areas are ideal for sealing leaks or cracks with Flex Seal.

Damage Level: Water penetration can be prevented with Drylok, but leaks and cracks cannot be sealed with it. Surfaces can be waterproofed and leaks can be sealed with Flex Seal.

Flexibility: Flex Seal dries to a hard, inflexible surface, whereas Drylok can bend and move with the surface.

Durability: Drylok provides protection for several years, while Flex Seal may need to be reapplied more frequently.

Read More: Turbo Poly Seal Vs. Flex Seal

Is Flex Seal Good for Basement Walls?

Is Drylok Flexible?

Does Drylok Need 2 Coats?

How Long Does Drylok Last?

Last Opinion

In summary, Drylok is a more specialized waterproofing product designed specifically for masonry surfaces, whereas Flex Seal is more versatile and can be applied to a variety of surfaces.

Flex Seal is a flexible coating that can move with the surface as opposed to Drylok, which is a hard, inflexible surface.

The best choice depends on the project’s specific needs, as both products have advantages and disadvantages.

Hopefully, you liked this comparison between drylok vs. flex seal. If you have any questions, please feel free to leave a comment below.