Finding the best panel bonding adhesive can be challenging because there are so many options on the market. What should you look for? Where should you shop? What should you do when there’s no panel bonding adhesive at your local store?

A car’s body panels are the exterior components that keep it from looking like an uncoordinated jumble of steel, metal, aluminum, and fiberglass. They take the brunt of road debris and weather damage but add to the car’s aesthetic appeal.

That’s why choosing the right panel bonding adhesive to fix a dented panel or secure your body trim can be so important to your restoration project’s success—and yours!

This article explains how to pick the right adhesive to fit your needs, even if it isn’t labeled as the panel bonding adhesive you need.

Read More: Best Epoxy For Plastic Gas Tank Repair

Top 5 Best Panel Bonding Adhesive: Reviewed in Detail

In this section, I will talk about some of the best panel bonding adhesives, you should know that every product may not work the same. Different products work differently. You should know about the product and decide what works for your situation.

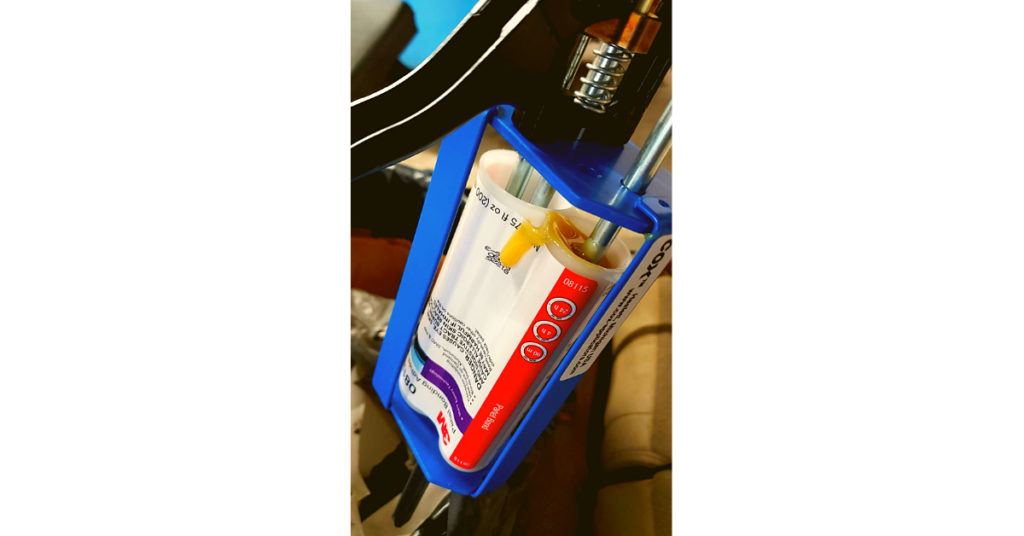

3M Panel Bonding Adhesive 08115

3M 08115 Specs And Features

- Comes in two different colors: black and purple

- Includes glass bead technology

- Two-part epoxy adhesive

- Have multiple uses like bonding door skins, quarter panels, box sides, roof skins, and bumper covers

- Comes in 3.98 ounces of weight

- Includes two static mixing nozzles

- Amazing adhesion

- It is suitable for occupational or industrial use only

3M 08115 Review

This 3M panel bonding adhesive is a good product as it works great. It has a wide range of bonding capabilities on different kinds of materials.

I know that the best adhesive is what not only works well but also satisfies the customers. If you see people recommending this product, you should consider it a good one.

You can choose this one if you are looking for a good product. 3M Panel Bonding Adhesive has all the facilities that meet your requirements and expectations. Not just that, even several OEMs also recommend this product.

The products are packaged and labelled well to sell to occupational and industrial customers. It is excellent to use on a variety of materials. It includes glass bead technology.

It helps to maintain a minimum bond thickness and protect against over-clamping. The 3M adhesive is also easy to use.

If you read genuine customer reviews, you know how people use them and get satisfactory results.

3M 08115 Pros And Cons

Pros

- Excellent for use on a variety of plastics

- Recommended by many OEMs

- Rapidly cured with heat

- Includes glass bead technology to protect against over-clamping

- Gives a professional look

Cons

- It may be allergic to the skin and irritate the eyes and nose.

Read More: 3M 08115 Vs. 08116

SEM 39747 Multi-Purpose Panel Adhesive

SEM 39747 Specs And Features

- Compatible materials are metal and fiberglass

- Comes in 7 fluid ounces weight

- Manufactured by SEM

- 100% permanent

SEM 39747 Review

This product is fantastic. This SEM 39747 is a multi-purpose panel adhesive that is a potent bonding agent that gives you permanent results. It is 100% permanent.

You can bond fiberglass and metals in a short time. Use it to bond the fiberglass panels on Corvettes and glue the metal brackets well.

Besides, this product is more beneficial to bond the panels together like body repairs and patch panels. It makes the cab corners and rocker panels stronger enough.

All you need is to clamp it. This adhesive is powerful that can bond the automotive panels without welding them. It is 100% permanent. So, you can get a strong bond if you use this adhesive.

Use it on different projects. I’m sure that you won’t regret it. Ensure that the parts should not squish at all when you clamp. One tip is to put a paperclip when you connect. And you can get better results.

SEM 39747 Pros And Cons

Pros

- Easy to use

- Worth the money

- Holds nicely

- Reasonable price

- You can bold automotive panels without welding

Cons

- It would help if you had a unique tool to use it

Read More: Best Weatherstrip Adhesive

3M Heavy-Bodied Seam Sealer 08308 Car Panel Adhesive

3M 08308 Specs And Features

- Heavy bodied

- Comes in 200 ml weight

- Included two parts epoxy seals vertical and horizontal seams to match ORM seals

- Has non-sag property aids while doing vertical appearances

- Comes in several colors like beige, black, white, and clear

3M 08308 Review

There is another good product from 3M, and that is the seam sealer heavy-bodied two-part epoxy. It is suitable for both vertical and horizontal applications. So, it matches the OEM seals correctly.

Besides, the car panel adhesive also includes dual syringe cartridges that have metered mixing abilities. It helps to minimize the tricky manual mixing. As a result, it creates less mess.

It is a good choice because of all the features it has. This sealer is non-flowing because it has non-sag properties. It allows the formula to cure fast while making vertical applications.

It is suitable for floor pans, door skins, roof seams, trunk floors, and many more. This self-mixing system makes all things more accessible.

3M 08308 Pros And Cons

Pros

- Easy tooling for matching the appearance of OEM seam sealer

- Non-flowing

- Cures quickly

- Perfect formulation

Cons

- The nozzle with the cartridge is bulky

J-B Weld 50139 Plastic Bonder Body Panel Adhesive

J-B Weld 50139 Specs And Features

- Color is black

- Comes in a 25 ml container

- Compatible materials are metal, fiberglass, concrete, plastic, carbon, and ceramic

- Syringe type container

- Secure fit

- Resealable

- OEM automotive and HD truck approved

J-B Weld 50139 Review

This product is considered the world’s strongest bond. The body panel adhesive and gap filler is a high-quality product that can provide a secure fit. The design is with the installer user in mind.

Moreover, the durability is tested and proven. So, you can be sure about the quality of this bonder. It comes in black color that has a multi-purpose two-part urethane adhesive quality and gap filling system.

The product gives you a long-lasting and strong bond to many plastic surfaces. Also, it comes in a syringe that makes the application easier.

You can use it on fiberglass, ceramic, concrete, plastic, coated metals, and aluminum. This product is a good one to use on several kinds of materials.

J-B Weld 50139 Pros And Cons

Pros

- Tested for durability

- Great for DIY plastic repairs, bumper repairs, and filling dents

- Cure quickly

- Great for filling gaps

- Prevents leaking and dying out

Cons

- A bit expensive

3M EZ Sand Multi Purpose Repair Material

3M EZ Specs And Features

- Two-Part Epoxy Finishing Adhesive

- Comes in a 200ml container

- Part of a complete repair system

- For industrial and occupational purposes only

- Suitable adhesion promoters and 3M applicator guns for added efficiency and speed

- Automotive plastic panel repairs are durable and flexible at the same time, along with matching OEM seam sealers

- Bonding is easily sandable; you need to wait around 15 minutes to get a smooth finish

- Paintable adhesive

3M EZ Review

The 3M sand multi-purpose repair is suitable for automotive plastic panel repair and OEM seam sealers that are both durable and flexible.

The proper ratio of the two-part epoxy adhesive is certainly metered. You can sand easily in 15 minutes for a smooth finish with no rework.

Besides, this product is paintable. It just takes 30 minutes or less to dry faster. For increased speed and efficiency, use with 3M applicator guns and also the adhesion promoters.

It makes the material easy to sand. These adhesives need 8 minutes to dry so that you can start the sanding process.

It is a part of a complete repair system from 3M. The unique qualities of this product make it easier to sand. Overall, it is a good one to buy.

3M EZ Pros And Cons

Pros

- Ready to use

- Durable and flexible

- Quickly paintable

- Easily sandable

- Nozzles included

Cons

- A bit harder to squeeze

Read More: Metal Glue Vs. Welding

What To Know Before Buying A Panel Bonding Adhesive?

I’m here to give you the information if you need more details to determine what product you should go for. Choosing a suitable adhesive can be irritating if you are new here. So, to make it easier, I recommend you to follow the facts and choose wisely.

Strengthening Capability

Any product depends on how much stress you intend to put on your newly purchased adhesive. If you need to put it through a lot of stress, I recommend getting a potent adhesive.

In this case, I recommend peel force, compression force, or tensile force. Select the adhesive wisely. And when you are dealing with high stress, go for glue that can handle the efficiency.

Time Limit to Cure

Keep in mind how much it takes to cure. Some adhesives work quickly. It makes the method easier. However, it is strict even when it comes to any mistake. If you apply the glue to any wrong surface, you cannot remove it quickly.

In this case, I suggest you go for that adhesive suitable for your work. Things will be easier to handle if you have experience in this sector.

Know Substrates

When buying an adhesive, you should first know about your substrates and their chemistry. For this reason, you should know almost everything about the materials you want to bond with. Some certain adhesives work well for ceramics and fiberglass, while the others work better with metals and plastics.

You need to know the difference to know what type of adhesive is suitable for specific materials. That’s how you can get the perfect bonding adhesive for your job.

Prepare Substrates

First, you need to prepare your substrates to keep the cleanliness locked. If the substrate is not clean enough, it cannot stick correctly. You have to make sure that you prepare the substrate for the method first. So, make sure of this thing while buying.

Environmental Situation

Another thing you need to be careful about is the environmental situation. The adhesive may stick well or not, depending on the changes in the weather. If you want to deal with a moderate climate, you have many adhesive options.

Also, if the weather is extremely hot or cold, you can find different varieties. According to all these things, you must be careful of what kind of adhesive you pick. So you don’t end up wasting your time.

Chemical Exposure

Lastly, it would help if you consider buying a panel bonding adhesive according to the chemical exposure. It will help if you have an idea about chemical exposure. The reason is if there is a bit of chemical exposure present, there is a chance that the adhesive doesn’t work in the long run.

For this reason, you should be sure about the adhesive and make sure it can resist any chemical exposure.

Last Opinion

Now that you know almost all about panel bonding adhesives, you can decide what type suits your job. Please ensure you know where you use it and what the material will be. And according to that, choose your best panel bonding adhesives.

Be sure what you want and purchase accordingly. Also, don’t forget to give us your feedback!